Transformer oil analysis is an important element in stable operation of the power system. Carrying out this analysis on a regular basis with the widest possible range of parameters included allow us to identify potential problems in the equipment operation with due advance, ensuring the smooth operation of the system and preventing possible alarm conditions. Analysis is exactly what becomes a prerequisite for preventing the alarm conditions and maximizing the efficiency of power systems.

Intended purpose of transformer oil

Transformer oil has been used in electrical transformers since the 19th century, when the famous engineer Elihu Thomson patented its use to remove heat from the transformer core, extending its service life.

While mineral oil still works well to this day, new alternative liquids are becoming increasingly popular, because they offer improved performance which contributes to extending the transformer service life, reducing the costs, and having a lower environmental impact.

All of these liquids are often referred to as liquid dielectrics. They are designed specifically to act as coolants and insulators in electrical transformers. The primary role of transformer oil is to ensure insulation for preventing an electrical breakdown and maintaining the required level of insulation between various components inside a transformer. They insulate the transformer’s conductive parts, such as the windings and the core, from the housing or the grounded tank, ensuring a continuous power transmission without leakage.

The insulating properties of oil are important for preventing the problems like short circuits and for ensuring the overall safety and reliability of a transformer.

Reasons for deteriorated condition of transformer oil in transformers

Transformer oil is a mix of various hydrocarbons. Exposure of oil to physical and chemical factors, such as heat, oxygen, electric arc, electric field, magnetic field, causes its physical properties, such as color, odor, kinematic viscosity, to change, and the changes gradually proceed to affect the electrical performance.

There are several reasons for transformer oil quality deterioration, including: oxidation, degradation, aging due to transformer malfunctions (overheating, short circuits), as well as poor technical supervision and negligent management during the transformer production, installation, and maintenance.

The key factor in transformer oil deterioration is oxygen.

No matter how good the transformer sealing performance is, transformer oil still contains a certain amount of oxygen. Moreover, the insulating material, paper fiber in the equipment, is also a source of oxygen, especially during the degradation process caused by heat.

The effect of water is equally significant. Water can penetrate into the oil from outside the equipment through ambient moisture and develop inside when cellulose aging occurs.

Many chemical reactions accelerate the oxidation process, including the presence of copper and iron in the system. When the operating temperature of transformer oil rises, the transformer vibration due to magnetostriction and electrical machinery increases the oil oxidation rate as well.

Classification of transformer oil parameters

The commonly analyzed transformer oil parameters are classified into several groups: physical properties, chemical properties, and electrical properties.

Electrical properties

Dielectric strength: defined as the minimum voltage at which oil begins to pass an electric current due to sparking between electrodes. The dielectric strength value is important for determining the ability of oil to insulate electrical components.

Resistivity: a measure of the electrical resistance of oil, normally evaluated at different temperatures. Low values at high temperatures may indicate impaired insulating properties.

Dielectric loss tangent: a parameter that represents the efficiency of insulating material as a dielectric. A low value indicates a high resistivity and good insulating properties.

Chemical properties

Water content: moisture in oil may considerably deteriorate its dielectric properties. The water content is measured in parts per million (ppm) and should be as low as possible.

Acidity: this parameter indicates the amount of free acids in oil, which may cause corrosion of metal parts and impair the insulating properties.

Physical properties

Interfacial tension: important for determining the ability of oil to repel water and other contaminants. High values indicate a good quality of dielectric material.

Flash point: a fire safety indicator that shows the temperature at which the oil may ignite. The higher the value of this parameter, the better the safety performance.

Viscosity: indicates the resistance of liquid to flow; ideally, the oil should have a low viscosity at low temperatures for better circulation.

Comprehensive and shortened analyses of transformer oil

New transformer oil is a clear light-yellow liquid that acts as a dielectric and a heat-removing medium. During operation, it gradually becomes darker and turbid, while its main physical, chemical, and dielectric properties change.

Transformer oil analysis can be carried out in accordance with a shortened and comprehensive procedure. In case of shortened analysis:

- visually assess the appearance, color, and turbidity of oil, the presence of mechanical impurities and free water;

- determine the breakdown voltage, the acid number, the flash point, and the water extract reaction.

During the comprehensive analysis of transformer oil, in addition to the shortened analysis, the following parameters are determined:

- Dielectric loss tangent at 90°C;

- quantitative content of mechanical impurities and water;

- gas content;

- presence of potential sludge;

- content of antioxidant additive, ionol;

- stability against oxidation.

Сhromatographic dissolved gas analysis of transformer oil is also carried out as part of comprehensive transformer oil analysis. This type of analysis provides virtually no information about the quality and condition of a dielectric, but it does provide diagnostic information about internal defects of a transformer. The fact is that the occurrence of a certain gas dissolved in oil is caused by a certain transformer defect.

The analysis of gas in transformer oil, especially the determination of their concentrations and the comparison of those with the limit values, makes it possible to diagnostically evaluate internal defects in transformers with an accuracy of up to 95%.

A comprehensive analysis of transformer oil is recommended when the express test data show the maximum allowable values, or when the oil performance dramatically changes.

GlobeCore transformer oil analyzers and the parameters they measure

Transformer oil is of crucial importance to ensuring the durability and efficiency of transformers. It acts as an insulating and cooling element that ensures the operational stability of the equipment. GlobeCore has developed a range of transformer oil express analyzers.

Water content

Moisture content of transformer oil is one of the most important parameters, because water considerably impairs its insulating properties and may cause corrosion of metal components. Water emulsion is particularly dangerous, because it may lead to rapid wear of insulating material.

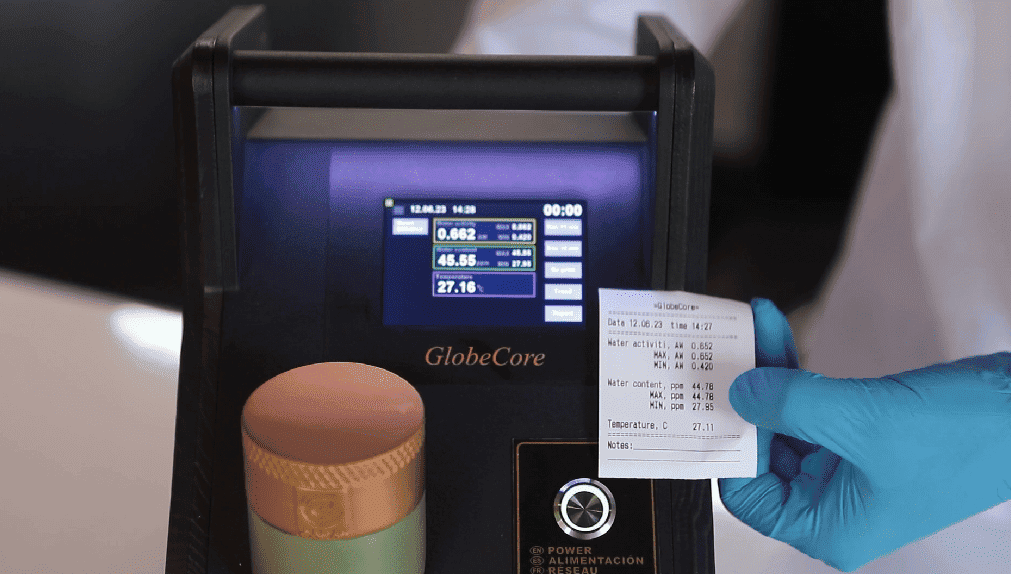

GlobeCore TOR-1 analyzer makes it possible to determine the moisture content of oil, even if the amount is negligible. The device uses a capacitance sensor to analyze moisture and is distinguished by compact design which allows taking measurements directly at the transformer operating site. This is ideal for online monitoring and immediate detection of moisture-related problems.

Measuring the amount of hydrogen

Hydrogen is one of the most important gases detected by chromatographic analysis. The development of this gas may indicate the occurrence of electrical defects. However, a comprehensive chromatographic analysis is time-consuming. As a solution, GlobeCore offers TOR-2 transformer oil express analyzer for determining the hydrogen content. The instrument is portable and can be used in the field. It allows for fast decision-making on site regarding the transformer maintenance.

Breakdown voltage

Breakdown voltage indicates the maximum electrical potential that transformer oil can withstand without losing its properties. It is a parameter that helps in ensuring the reliability and safe operation of a transformer under high-voltage conditions.

GlobeCore TOR-60, TOR-80, and TOR-100 instrument model ranges specialize in measuring this parameter. The instruments are portable and can perform testing at 60, 80, and 100 kV respectively.

The measuring process is automated, the instruments ensure accurate measurements with a minimum measurement tolerance, and if necessary, they may also be equipped with a battery, which makes it possible to analyze transformer oil in the field.

Dielectric loss tangent

GlobeCore TOR-3 tester is designed to accurately determine this tangent. Like other instruments in this range, it is portable, which makes it easy to move about the lab. This instrument allows judging the condition of oil on the spot and ensures automated measuring and result storing.

GlobeCore TOR transformer oil analyzers offer the following advantages:

- Reliability and accuracy of measurements: TOR instruments ensure a high accuracy of analysis, which is important for the safety and efficiency of transformers.

- Ease of use: their compact and ergonomic design makes them easy to transport and use, especially at the sites with confined space.

- High rate of analysis: the devices allow for fast testing, ensuring the prompt results and maintaining the stable operation of transformers.

- Saving of time and money: optimized maintenance planning reduces the risk of unexpected repairs and extends the service life of transformers.

- Multipurpose use: the instruments are suitable for both laboratories and production facilities, which allows carrying out the analyses of oil samples on a real-time basis and in any settings.

Regular use of transformer oil analyzers helps identifying the potential problems in an effective way, preventing alarm conditions and maintaining the power supply reliability.

Hydrogen and Moisture ...

Hydrogen and Moisture ... OIL TAN DELTA ...

OIL TAN DELTA ... Breakdown Voltage Tester ...

Breakdown Voltage Tester ...