A transformer oil hydrogen analyzer is an indispensable tool for power-generating companies interested in timely diagnostic evaluation of transformers.

Methods of detecting the defects that may develop in transformers

A transformer oil hydrogen analyzer is widely used in the energy sector. That’s because dissolved gases help in identifying 80% of all defects in transformers. All of this is due to the fact that thermal or discharging processes in the transformer insulation cause its degradation and the development of dissolved gases. The most common gases are hydrogen, oxygen (O2), nitrogen (N2), methane, ethane, ethylene, acetylene, carbon monoxide, and carbon dioxide. The ASTM D3612 standard describes three methods for dissolved gas removal from oil.

The first method uses vacuum extraction and involves the use of mercury, which poses health hazards. The device is complex, it contains many valves and requires expensive vacuum gauges to detect leaks in the system. However, the main disadvantage of this method is that it takes up a lot of time. In order to detect almost all the dissolved gases, it is necessary to carry out two or three extractions from an oil sample which is neglected in many laboratories and affects the quality of results. The other method according to ASTM D3612 uses a stripping column with a large surface area; this method has a low accuracy and is hardly ever used. The method of using a gas chromatograph has become the most frequent practice.

Method for chromatographic dissolved gas analysis of transformer oil

Chromatographic analysis is the most common method for early detection of changes in transformer insulation and potential faults of a transformer. According to the ASTM D3612 standard, the prepared oil sample is injected into the chromatograph. Having passed through the chromatographic column, constituents are selected from the dielectric by their chemical properties. Next, they pass through a detector that records their presence for further analysis and determination of concentrations.

Based on the results of gas chromatography, it is possible to diagnostically evaluate the main causes of insulation degradation which are classified into six typical problems with the following visible consequences:

- partial discharge;

- low-energy discharge;

- high-energy discharge;

- thermal damage (up to 300 °C);

- thermal short circuit (above 300 °C);

- thermal short circuit (over 700 °C).

It often happens that one phenomenon develops into another, or that two phenomena occur simultaneously. Knowing the concentrations of certain gases, we can proceed to choose the method by which we will interpret them. There are plenty of interpretation methods, including the Roger correlation coefficient, the IEC method derived therefrom, the Dornenburg correlation coefficient, the Duval triangle, etc. All of them are used in gas ratio calculations to determine various statuses of a transformer.

The main advantages of this analysis method include the commercial availability and considerable gas removal precision of a chromatograph. The disadvantages include the fact that research takes a certain amount of time — first for release of gases, and then for calculation of their concentration.

Transformer oil hydrogen analyzer

Each type of transformer oil analysis has its own schedule. Thus, the accumulation of acidic compounds and the formation of furans occur very slowly, so an analysis for their detection can be carried out once every couple of years. While the release of a large amount of gases indicating a fault may occur in a few hours.

Even the IEEE C57-104-2019 standard revised its requirements, recommending that the frequency of dissolved gas analysis be increased from annual to daily testing. These recommendations are based on case studies that describe the cases where this analysis detected a progressive fault that technicians might have missed during an annual analysis.

However, not all companies have the opportunity to carry out a chromatographic analysis every day. Testing takes a certain amount of time, increases the lab load, which protracts obtaining the results. The solution offered by GlobeCore is a TOR-2 transformer oil hydrogen analyzer. The analyzer makes it possible to quickly detect the content of hydrogen, a gas that is key to chromatographic analysis, in transformer oil.

This is due to decomposition chemistry where the temperature increases in the presence of damage; hydrogen in oil develops in the event of every temperature-induced damage. Other gases come and go as the temperature changes, but the amount of hydrogen in transformer oil just increases.

Therefore, having noticed an increase in the amount of hydrogen according to the express analysis results, the technicians can make a faster decision to carry out a complete chromatographic analysis or take other measures if required.

Advantages and benefits of using the TOR-2 transformer oil hydrogen analyzer

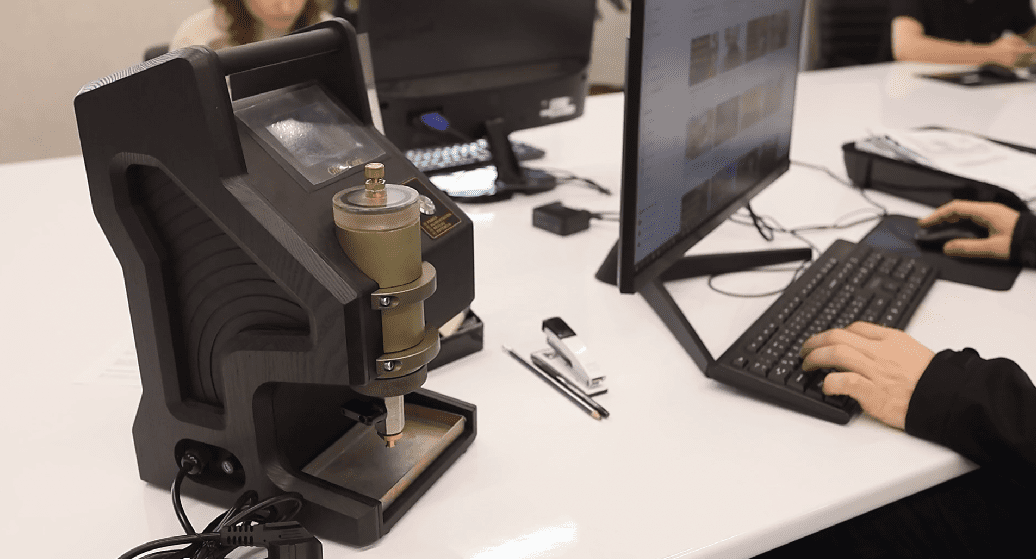

The TOR-2 transformer oil hydrogen analyzer is designed for express analysis of moisture and hydrogen in insulating oils.

The instrument combines a pair of capacitance and solid-state sensors to ensure direct measurement of hydrogen and moisture in oil. This allows obtaining prompt and accurate results, even during operation in the field, without spending on consumables and maintenance.

The TOR-2 transformer oil hydrogen analyzer:

- allows measuring hydrogen directly in the field;

- calculates the moisture and hydrogen content in parts per million (ppm);

- uses special sensors which are insensitive to contaminants in oil;

- contains no membranes or other consumables. Requires no special maintenance.

The TOR-2 transformer oil hydrogen analyzer is an efficient instrument for monitoring the level of hydrogen in transformer oil. It ensures fast and accurate measurement of hydrogen and water concentration which allows responding to any deviations in a prompt manner and performing a preliminary diagnostic evaluation of the transformer status. This kind of monitoring for dissolved gas in transformer oil is key to managing a substation and ensures the operational reliability of a transformer and the power-generating system.

Hydrogen and Moisture ...

Hydrogen and Moisture ... OIL MOISTURE METER ...

OIL MOISTURE METER ... OIL TAN DELTA ...

OIL TAN DELTA ...