A transformer oil moisture tester is indispensable in electrical labs and organizations that operate transformers or deal with their maintenance.

Ways of moisture ingress into the transformer

A transformer oil moisture tester is important in routine

monitoring of the equipment for proper functionality. After all, with aging, moisture can accumulate in the transformer tank. Water can enter transformers in various ways and even develop from the inside. Thus, while paper insulation and dielectric material are aging, there develops moisture as a byproduct of chemical reactions. Along with that, in this case, the acidity level increases, there develop signs indicating the formation of furans (a product of insulation degradation), and the dielectric strength decreases.

Moisture can be absorbed by the winding and by oils from the air due to the system sealing failure. Furthermore, the mechanical parts such as bushings, caps, radiator flanges, manometer, or pressure relief devices may begin to leak as they age. If the moisture level in the oil is high, it also affects the paper insulation.

Using the wet equipment, regardless of the model, causes a lot of problems. Let’s consider in greater detail the danger of moisture in transformers and how to prevent its occurrence.

Probable adverse effect of moisture on a transformer

Without moisture level monitoring, transformers may undergo the following changes:

- accelerated aging processes: the moisture contained in the transformer may cut the time of its operation in half. After all, the water remaining inside the transformer for a long time causes corrosion processes, developing rust, and deteriorated condition of the structural metal parts;

- frequent failures — unlike transformer oil, water is a poor conductor of heat, which disrupts the cooling system operation. Due to this, the transformer is more likely to overheat and fail which may lead to inevitable problems as time goes by.

- increasing power consumption — as affected by moisture, the transformer insulation resistance can increase, which may lead to an increase in power consumption and a deterioration in transformer performance.

- insulating strength decreases — moisture damages the transformer insulation which may lead to transformer malfunctioning.

- fire hazard: if the level of moisture saturation is too high, the risk of arcing or short-circuiting increases.

Normalization of moisture in transformer oil

According to the standards, the moisture content of a new transformer shall not exceed 0.5% of the paper insulation weight and contain less than 10 mg/kg of water as specified in IEEE C57.106. Thus, for example, a new transformer with the paper insulation and the oil weighing 5,000 kg and 20,000 kg respectively will contain 25 kg of water in the paper insulation and about 200 g of water in the oil.

The averaged moisture values for new oil are 13–30 ppm according to IEC 60296 and 65 ppm for waste oil.

At the same time, the known saturation of oil with moisture helps in calculating the moisture content of paper windings which is more difficult to measure using an instrument method. Thus, according to IEEE C57/106:2006, when the oil moisture is less than 5%, the paper insulation is considered dry; at 5–20%, the insulation is considered moderately wet, depending on the exact value; when the saturation is more than 20%, the windings are considered wet.

Express test of moisture in transformer oil

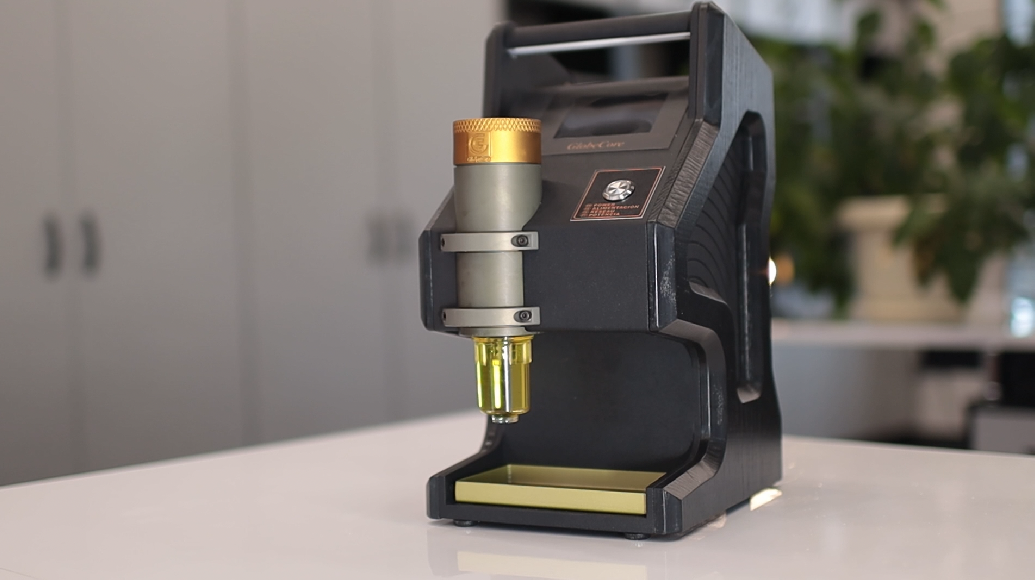

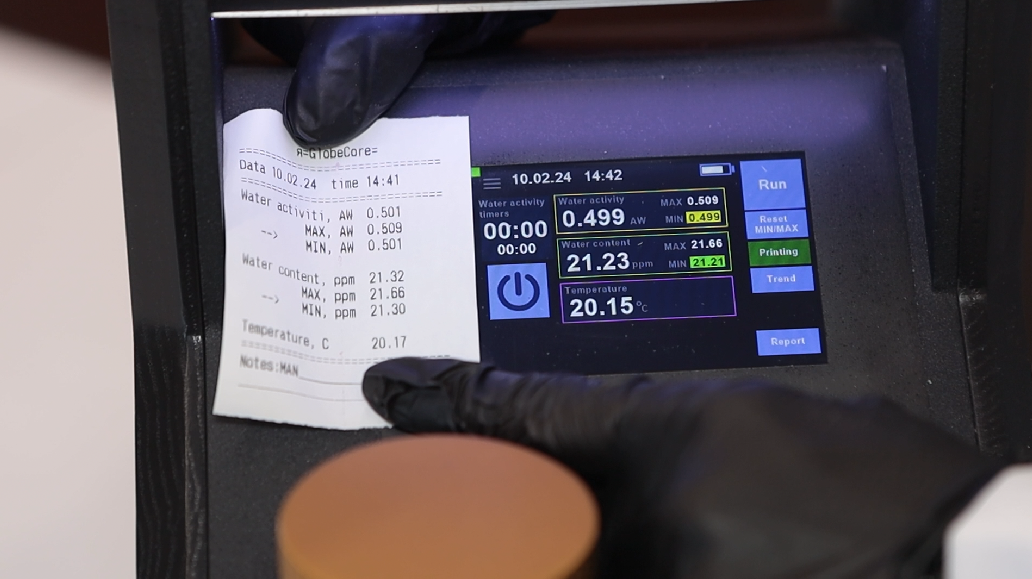

Moisture is a considerable factor that can may stop the operation of a transformer. Unfortunately, it is not always possible to trace changes in the composition of oil, to seize the opportunity when moisture has just appeared and did not get a chance to cause serious damage. In order to facilitate the work of technical teams, GlobeCore has developed a solution — TOR-1 transformer oil moisture tester. It allows performing a primary analysis of transformer oil promptly in the field and detecting the moisture content. This helps in saving time and money on performing analyses in the lab and, if required, in taking urgent measures to prevent the occurrence of serious failures.

Measurement by means of TOR-1 is facilitated by a capacitance sensor. The upgraded model of the tester includes a heating and stirring system. This allows ensuring the solubility of moisture in the sample and making the instrument readings independent on the ambient temperature to obtain more accurate results. Furthermore, the sensor used is insensitive to other contaminants; thus, they don’t affect the readings.

And full automation of the analysis process is facilitated by software upgrades. After filling the cell, the result is returned once the maximum and minimum moisture content calculation is completed, which takes up to 10 minutes.

Advantages of TOR-1 transformer oil moisture tester

The TOR-1 transformer oil moisture tester will be a useful addition to power transformer maintenance as it helps in preventing the costly water damage. Monitoring the moisture level, technicians can take the appropriate measures.

The tester allows analyzing the oil in the field owing to an integrated rechargeable battery. The battery can withstand a prolonged discharge, a cyclic discharge, a deep discharge, and a high-current discharge, features low self-discharge rates during long-term storage and a reliable self-protection against overcharges and excess charges.

The upgraded model also includes an RGB backlight which indicates the testing stages. The backlight color changes from orange at the analysis start to green when the results are available.

The TOR-1 transformer oil moisture tester will allow conducting a diagnostic evaluation of transformer oil as soon as possible and taking prompt measures without awaiting the electrical engineering lab analysis results. All of this is feasible in the most remote areas, in the field, just near the transformer, even without connecting the instrument to external power supply.

TOR-1 moisture tester allows responding to the system status in a prompt manner which makes it possible to avoid the defects developing in transformers and to enhance their reliability.

OIL MOISTURE METER ...

OIL MOISTURE METER ... Hydrogen and Moisture ...

Hydrogen and Moisture ... OIL TAN DELTA ...

OIL TAN DELTA ...