Transformer oil testers are some of the fastest and most affordable methods for evaluating the state of transformer. After all, transformer oil contains nearly 70% of diagnostic information about the state of equipment.

In order to maintain the optimal state of your transformers in various industries ranging from public utility to industrial power sectors, transformer oil analysis can help you understand the current performance issues or prevent malfunctions and potential problems in the future.

In this article, we are going to take you through the special aspects of transformer oil testing and the reasons why it is important to carry out a transformer oil analysis.

Role of dielectric liquid in transformers

Transformer oil, also known as insulating oil, is a special liquid characterized by strong electrical insulating properties and stability at high temperatures. This type of oil is mainly used in oil-filled power transformers, performing a number of important functions. These include ensuring the insulation, reducing the probability of arc and corona discharges, as well as effective heat removal, i.e. acting as a coolant to maintain the optimal transformer performance.

Furthermore, the oil serves to protect the transformer core and the windings contained therein, preventing the direct interaction of ambient oxygen with cellulose, thereby minimizing the oxidation process. It also helps in removing heat from the core and, ultimately, provides some insight into the state of transformer.

Transformer oil properties

In order to determine the suitability of transformer oil for use, several types of properties should be factored in: electrical, chemical, and physical.

The electrical properties of insulating oil include resistivity, dielectric strength, and dielectric loss tangent.

Dielectric strength, or breakdown voltage (BDV), indicates the ability of oil to withstand electrical voltage without degradation. A low BDV indicates the presence of moisture and conductive substances. BDV is measured by means of electrodes immersed in the oil inside an enclosed cell and gradually increasing the voltage until sparking has occurred. A good oil should have a BDV of at least 30 KV.

Resistivity characterizes DC resistance per unit volume of oil. It should be high at indoor temperature, as well as at elevated operating temperatures. The minimum standards at 27°C and 90°C are set at the levels of 1500 × 10^12 ohm-cm and 35 × 10^12 ohm-cm respectively.

Dielectric loss tangent is indicative of imperfect dielectric properties. A high tan delta indicates the presence of contaminants that reduce the resistive properties. A low tan delta value is preferable for effective insulation.

Chemical properties include water content, acidity, sludge content, analysis of furanic compounds (cellulose aging), and dissolved gas analysis (DGA). Water content, which adversely affects the dielectric properties of oil and paper insulation. Hygroscopic paper absorbs water from the oil, reducing the insulation efficiency. Water solubility increases as oil temperature rises, which affects the release of moisture from the paper.

Acidity, which accelerates oil oxidation, damages the insulation and contributes to occurrence of rust. An acidity test measures the level of acid contaminants and is expressed in mg KOH required to neutralize the acid per gram of oil.

Physical properties include interfacial tension, viscosity, viscosity and color.

Interfacial tension (IFT) characterizes the attractive forces between water and oil molecules. A high value indicates a high quality of oil, while oxidizing impurities cause its downgrade.

Flash point is the temperature at which oil vapors form a flammable mixture with air. A high flash point (>140°C) reduces the fire safety.

Pour point is the minimum temperature at which oil flows. In cold climates, it is vitally important to ensure proper oil circulation and cooling in transformers. A low viscosity contributes to oil circulation and cooling. It is crucial to keep the viscosity stable in response to temperature changes.

Transformer oil analysis

There are 17 common transformer oil test methods in total. Some of those are part of the required routine tests, while others, such as detection of furans and corrosive sulfur, help in obtaining further insight into diagnostic evaluation, or are required for certain certifications.

Various tests defined by international standards, such as the American Society for Testing and Materials (ASTM), measure different properties of oil. The most common tests apply to hydrogen level, moisture level, dielectric breakdown voltage, and dielectric loss tangent. These tests help you determine the suitability of oil for further use, identify the need for regeneration or filtration, reduce costs and prevent premature failures.

The appropriate insulating oil tests and the targeted diagnostic evaluation allow you to do the following:

- Detect faults and malfunctions;

- recognize faults at an early stage and thus prevent them from occurring;

- plan maintenance activities and evaluate the state of the entire transformer fleet;

- maximize the performance of transformers and extend their service life.

GlobeCore transformer oil testers and their specifications

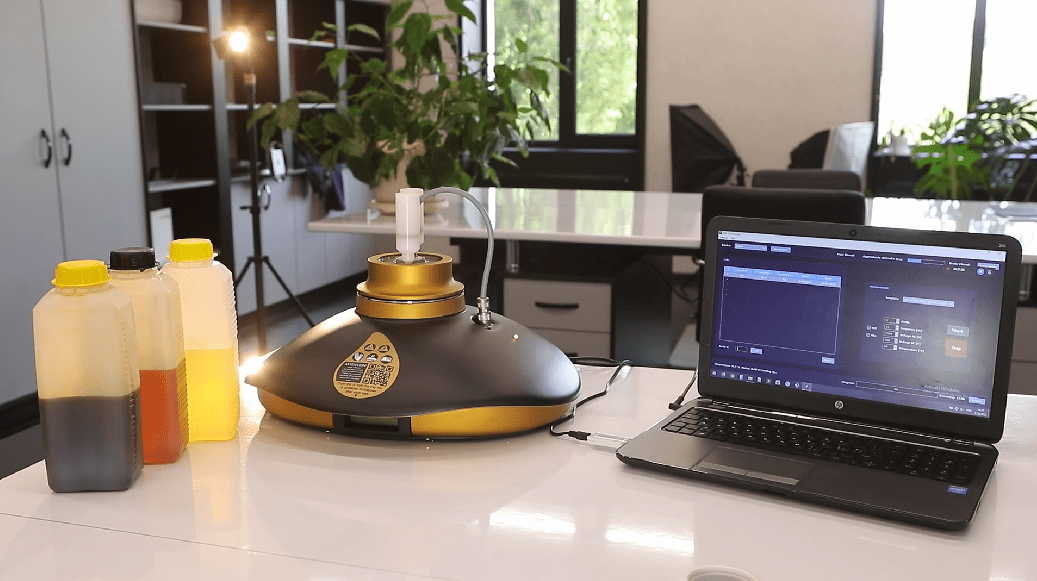

GlobeCore has developed transformer oil testers, which mean instruments to measure the main parameters of transformer oil.

Water content

Hydrogen content measurement

Breakdown voltage

Breakdown voltage indicates the maximum electrical potential that transformer oil can withstand without losing its properties. It is a parameter that helps in ensuring the reliability and safe operation of a transformer under high-voltage conditions.

GlobeCore TOR-60, TOR-80, and TOR-100 breakdown voltage testers for transformer oils specialize in measuring this parameter. The instruments are portable and capable of performing tests at 60, 80, and 100 kV respectively. The measuring process is automated, the instruments ensure accurate measurements with a minimum measurement tolerance and may also be equipped with a battery, which makes it possible to analyze transformer oil in the field, if required.

Dielectric loss tangent

Dielectric loss tangent represents energy losses in transformer oil caused by contaminants and aging. A change in the loss tangent may indicate the deteriorated quality of oil and the need for oil change and purification. GlobeCore TOR-3 tan delta tester is designed to accurately determine this tangent. The tester is portable, which makes it easy to move about the lab, which allows judging the condition of oil on the spot and ensures automated measuring and result storing.

Advantages of GlobeCore TOR transformer oil testers

The TOR transformer oil express testers ensure a high accuracy of analysis, which is important for the safety and efficiency of transformers. Their compact and ergonomic design makes them easy to transport and use, especially at the sites with confined space. Optimized maintenance planning reduces the risk of unexpected repairs and extends the service life of transformers. The instruments are suitable for both laboratories and production facilities, which allows carrying out the analyses of oil samples in the field.

Regular use of transformer oil testers helps the effective identifying of potential problems with alarm conditions prevented and the power supply reliability maintained.

OIL MOISTURE METER ...

OIL MOISTURE METER ... Hydrogen and Moisture ...

Hydrogen and Moisture ... Breakdown Voltage Tester ...

Breakdown Voltage Tester ...